Duncan Made Damascus

Ron's knives are available in simple carbon steels for the

purists and also ultra-tough tool steels such as 5160 and

L6.

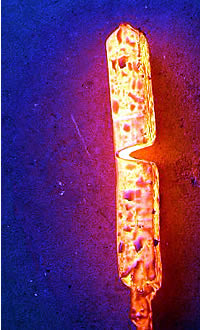

But Ron is well known for his bold damascus patterns. These

patterns are not achieved by chance. Rather they are carefully

planned and constructed from choice steels. Ron starts with

simple carbon steels such as 1084 and 1095. He then blends

them with tool steels such as L6 and 15N20.

|

These steels are welded together to form

a solid billet of blended steels. Of course the process

does not end there. The billet is cut, folded over,

and re-welded.

The process creates patterns that not

only add strength to the finished blade, but beauty

as well.

|

|

|

|

Over and over the steel is cut, folded,

welded. In fact the entire process creates from 1,000

to 10,000 layers of steel. This is the same process

used by Japanese swordsmiths for over 500 years.

|

Is it worth the effort? Judge for yourself,

but the high demand for Duncan Made Knives ultimately answers

the question.

Another exciting source of damascus is chainsaw

chain.

Return to

Knife Making.

Learn more about Finishing

the Knife.

|